Bar Clamps: A Complete Guide for DIY Enthusiasts

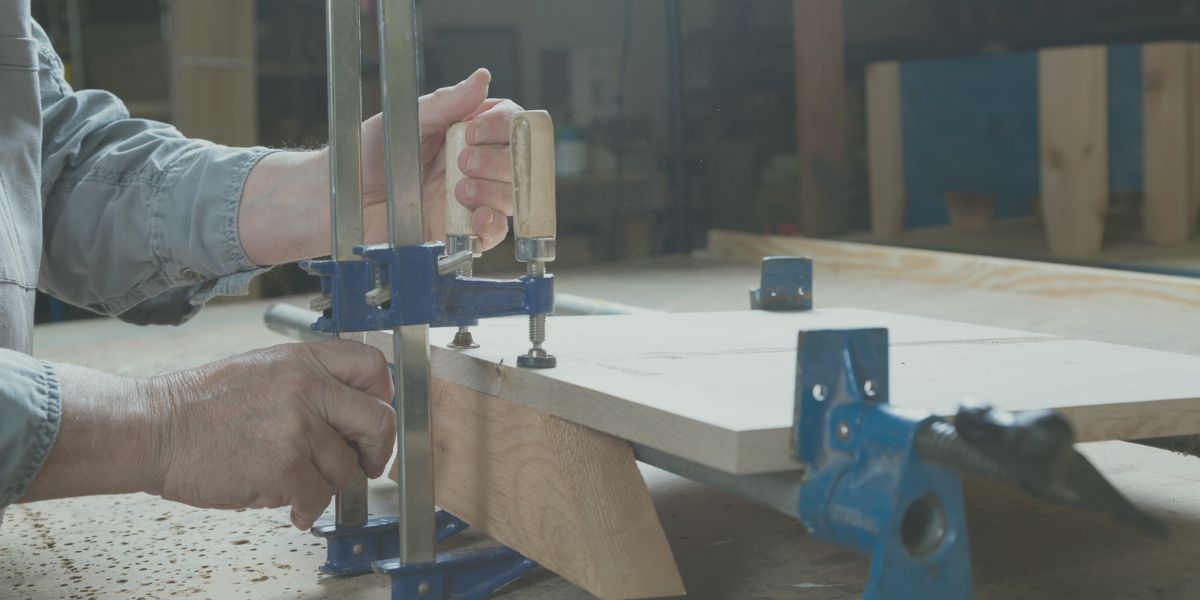

Bar clamps are essential tools for woodworking, metalworking, and various DIY projects. They are designed to hold and secure materials, such as wood or metal, in place while you cut, drill, glue, or fasten them.

This complete guide will provide a comprehensive overview of bar clamps, their types, key features, how to choose the right one for your needs, usage and safety tips, maintenance and storage, and popular brands and models.

Table of Contents

- Types of Bar Clamps

- Key Features and Components

- How to Choose the Right Bar Clamp

- Proper Usage and Safety Tips

- Maintenance and Storage

- Popular Brands and Models

- Conclusion

Types of Bar Clamps

- F-Clamps

F-clamps, also known as bar clamps or speed clamps, are versatile and easy to use. They feature a sliding jaw that can be adjusted quickly along the bar and tightened with a screw mechanism. F-clamps are ideal for woodworking, as they offer excellent clamping pressure and can accommodate different material thicknesses.

- Parallel Clamps

Parallel clamps are designed for precise and even pressure distribution, making them perfect for tasks requiring accurate alignment, such as gluing panels or cabinetry. They have jaws that remain parallel to each other during clamping, ensuring that the workpiece stays flat and square.

- Pipe Clamps

Pipe clamps are an affordable and customizable option for DIY enthusiasts. They consist of a clamp head and tail that attach to a length of pipe, allowing users to create clamps of various sizes based on their project requirements. These clamps are suitable for large-scale projects, such as building furniture.

- Quick-Grip Clamps

Quick-grip clamps, also known as one-handed bar clamps, are designed for fast and easy clamping with one hand. They have a trigger mechanism that allows users to adjust the clamp's pressure quickly and release it with ease. These clamps are ideal for light-duty tasks and quick fixes.

Related Article: What is a C-Clamp?

Key Features and Components

- Clamping Pressure

Clamping pressure is the amount of force exerted by the clamp on the workpiece. It is essential to choose a clamp with adequate clamping pressure for your project to ensure that the materials are held securely in place.

- Bar Length and Material

Bar length determines the maximum width of the material that can be clamped. Bars can be made from steel, aluminum, or other materials, each offering different levels of strength and durability. Choose a bar clamp with a suitable length and material based on your project's requirements.

- Jaws

The jaws of a bar clamp hold the workpiece in place. They can be made from various materials, such as plastic, wood, or metal, and may feature protective pads to prevent damage to the workpiece. Consider the size and material of the jaws when selecting a bar clamp.

- Throat Depth

Throat depth refers to the distance between the top of the jaw and the center of the clamp's screw. This measurement determines the maximum thickness of the material that can be clamped. Ensure that the throat depth of the clamp you choose is suitable for your project.

How to Choose the Right Bar Clamp

1. Determine the type of clamp needed based on your project requirements.

Different types of bar clamps are suited for various tasks. For example, F-clamps are versatile and perfect for woodworking projects that require strong clamping pressure, while parallel clamps are ideal for tasks that need precise alignment, such as gluing panels. Assess your project's needs and choose a clamp type accordingly.

2. Consider the clamping pressure required for secure and accurate clamping.

The clamping pressure varies among different types of bar clamps. For heavy-duty tasks or projects that involve dense materials, such as hardwood, it is essential to select a clamp with a high clamping pressure to hold the workpiece securely in place. For lighter tasks or delicate materials, a clamp with lower clamping pressure may be more suitable to avoid damaging the workpiece.

3. Evaluate the desired bar length and material to accommodate your workpiece.

The bar length determines the maximum width of the material that can be clamped. For example, if you are working on a project that requires clamping 36-inch wide panels, you should choose a bar clamp with at least a 36-inch bar. The material of the bar also plays a role in the clamp's strength and durability. Steel bars are typically stronger than aluminum bars, but they may be heavier and more susceptible to rust.

4. Assess the jaw size and material to prevent damage to your materials.

The jaws of a bar clamp hold the workpiece in place and can be made from various materials, such as plastic, wood, or metal. When selecting a bar clamp, consider the size of the jaws to ensure they can adequately grip your workpiece. Additionally, pay attention to the jaw material and whether it features protective pads. For delicate materials or surfaces, choose a clamp with non-marring pads to prevent damage.

5. Ensure that the throat depth is appropriate for the thickness of your workpiece.

The throat depth of a bar clamp refers to the distance between the top of the jaw and the center of the clamp's screw. This measurement determines the maximum thickness of the material that can be clamped. For instance, if you are working with 3-inch thick boards, you would need a clamp with a throat depth of at least 3 inches. Select a bar clamp with an appropriate throat depth based on the thickness of the materials you plan to work with.

Proper Usage and Safety Tips

- Always wear safety gear, such as goggles and gloves, when working with bar clamps.

- Ensure that the clamp is properly adjusted to fit the workpiece securely without over-tightening.

- Use the appropriate number of clamps for the size and weight of your materials.

- Inspect the clamp for any signs of wear or damage before use.

- Follow the manufacturer's instructions for proper usage and care.

Related Article: What You Need To Know About Spring Clamps

Maintenance and Storage

- Keep your bar clamps clean and free of debris by wiping them down after each use.

- Lubricate the screw and sliding mechanisms regularly to ensure smooth operation.

- Store your clamps in a dry and cool location to prevent rust and corrosion.

- Organize and hang your clamps on a clamp rack or pegboard for easy access and space-saving storage.

Popular Brands and Models

- Bessey: Known for their high-quality and reliable clamps, Bessey offers a wide range of bar clamps, including F-clamps, parallel clamps, and pipe clamps.

- Jorgensen: Jorgensen is a trusted brand for woodworking tools, offering durable and sturdy bar clamps, such as their Cabinet Master parallel clamps and Pony pipe clamps.

- Irwin: Irwin's Quick-Grip clamps are popular among DIY enthusiasts for their ease of use and versatility in various projects.

- DeWalt: DeWalt offers a range of heavy-duty bar clamps designed for professional use, such as their Medium and Large Trigger Clamps.

Conclusion

Bar clamps are an indispensable tool for DIY enthusiasts, providing secure and accurate clamping for various projects. By understanding the different types of bar clamps, their key features, and how to choose the right one for your needs, you can ensure successful and efficient completion of your projects.

Additionally, proper usage, maintenance, and storage of your clamps will prolong their lifespan and guarantee their reliability. With the right bar clamp in hand, you can tackle any DIY project with confidence and precision.